Geowell provides a unique service offering of well completion and intervention accessories. We can offer to provide threaded accessories and connection threading, slickline and thru-tubing tools and also perform print part manufacturing to order, using state of the art technology and quality systems.

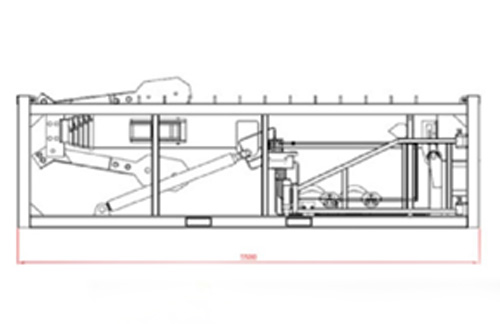

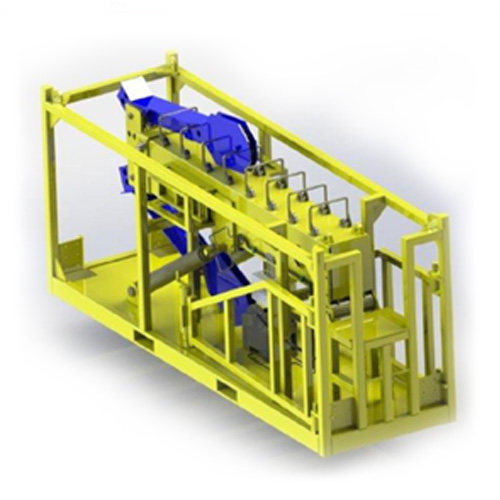

70ft Wireline Mast

Feature:

- Hydraulically operated mast sections are easily erected by 2 men in approximately 15 minutes. The mast can be extended to 70ft and requires an external hydraulic powerpack.

- With a high safe working load, this unit is designed for light to heavy duty slickline operations, and can withstand strong side winds.

- This telescopic wireline mast is compact, rigid and stable, for work in the toughest conditions.

- All-steel construction – for maximum strength in minimum dimensions.

- Locked each boom’s column for extensive safety features.

- The lock operator console with stainless steel color coded engraved with English letter.

Dimensions & Weights

- Transport Dimensions: (L) 5500 mm, (W) 1200 mm, (H) 1930 mm

- Weight: 4,800 kg

- Height: 70 feet

Technical Specification

- Under Hook Height (m): 21.50

- Column Safe Working Load (Kgs): 10,000

- 1st Winch Lift and Hold Capacity (Kgs): 2,500

- 2nd Winch Lift and Hold Capacity (Kgs): 1,500

- Foot Print (m): 6.715 x 4.015

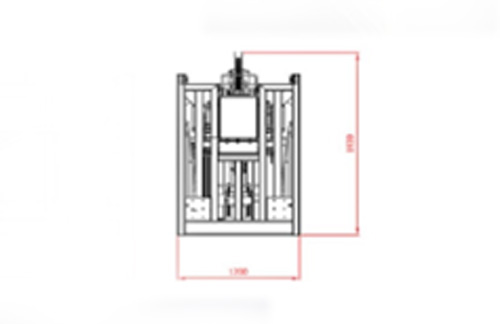

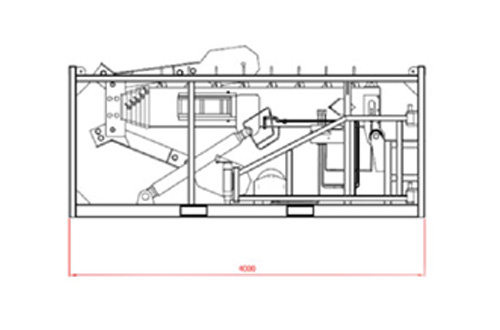

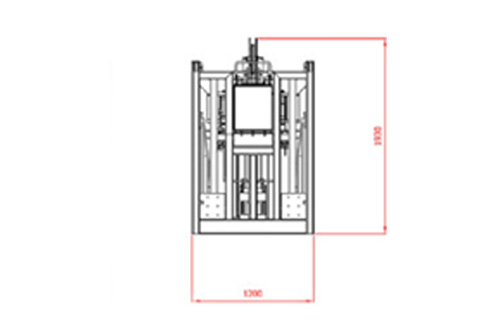

40ft Wireline Mast

Feature:

- Hydraulically operated mast sections are easily erected by 2 men in approximately 15 minutes. The mast can be extended to 40ft and requires an external hydraulic powerpack.

- With a high safe working load, this unit is designed for light to heavy duty slickline operations, and can withstand strong side winds.

- This telescopic wireline mast is compact, rigid and stable, for work in the toughest conditions.

- All-steel construction – for maximum strength in minimum dimensions

- Locked each boom’s column for extensive safety features

- The operator console with stainless steel color coded engraved with English letter.

Dimensions & Weights

- Transport Dimensions: (L) 4000 mm, (W) 1200 mm, (H) 1930 mm

- Weight: 3,500 kg

- Height: 40 feet

Technical Specification

- Under Hook Height (m): 12.00

- Column Safe Working Load (Kgs): 10,000

- Winch Lift and Hold Capacity (Kgs): 1,500

- Foot Print (m): 5.290 x 4.015

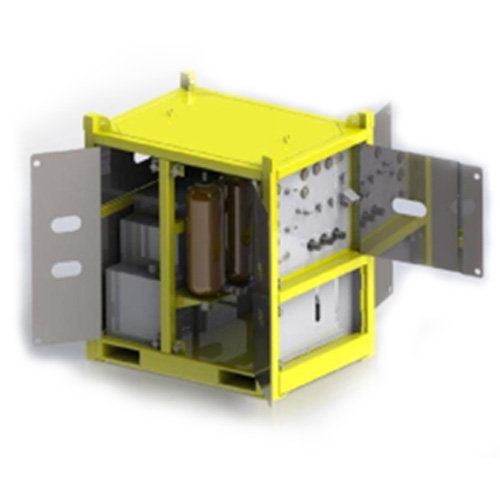

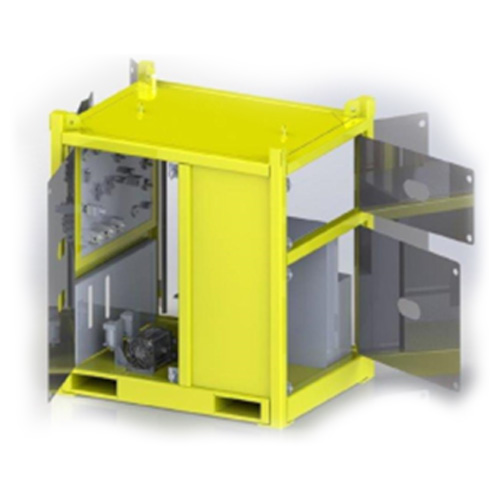

10K-PSI Wellhead Control Panel

Feature:

- Application for Dual RAM – BOP Control Panel and to actuate SCSSV and SSV by hydraulic

- 20-liters and 55-litres Hydraulic Reservoir Tank

- 40 liters Accumulator for back up operation of BOP (can be operated 3 times open-close-open for BOP size 7”, below that size can be more than 3 times)

- High quality valves, gauge, tubing and fittings

- Emergency Shutdown (ESD) System for BOP, SCSSV and SSV (automatically closed) from remote up until 30 meters

- Complete with 10 liters Air Receiver Tank, as back up when no source of air found

- Complete with manual back up hand pump to run SCSSV and SSV.

Dimensions & Weights

- Transport Dimensions: (L) 1450 mm, (W) 1100 mm, (H) 1622 mm

- Weight: 2,000 kg

Technical Specification

- Pump specification for BOP:

- Air driven Pump, AW-52

- Pressure outlet, max; 8,000 psi

- Flow: 30 litres/minute

- Pump specification for SCSSV and SSV:

- Air Driven Pump, MHP-110

- Pressure outlet, max: 13,500 psi

- Flow: 2.0 litres/minute

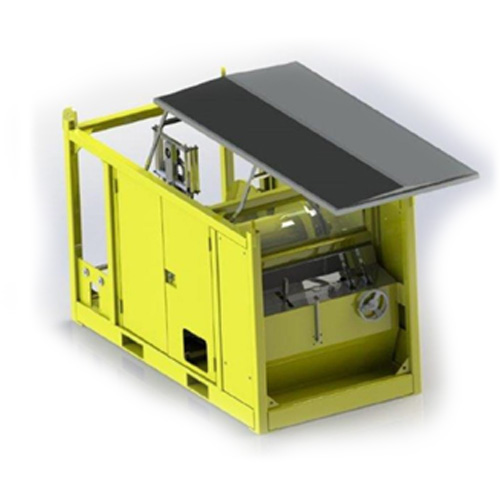

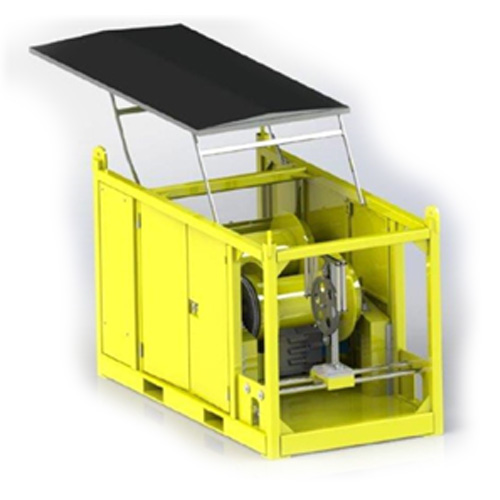

Double Drum Unit

Feature:

- Reel Capacity:

- Upper Drum: 25,000 Feet of 0.105” Wire, interchangeable with 0.125” Wire

- Lower Drum: 25,000 Feet of 0.125” Wire, interchangeable with 0.140” Wire.

- Gear Box: 4-Speed Heavy Duty Funk Transmission.

- Splitter Gearbox to Change Drive between Drums, reduce noise and vibrate.

- Duplex Sprockets and Chain Drive Power Transfer.

- Dual Handle Operated Band Brakes One for Upper Drum and One for Lower Drum.

- Hand Wheel Drive Level Wind Mechanism for Measuring Head Assembly Both Wire.

Dimensions & Weights

- Transport Dimensions: (L) 2600 mm, (W) 1320 mm, (H) 1611 mm

- Weight: 3,000 kg

Technical Specification

- Hydraulic Motor Vickers 35M115:

- Displacement: 7.44 in2/rev (121.9 cc/rev)

- Torque: 115 lb.in / 100 Psi.

- Maximum Pressure: 175 bar (2537.5 Psi.).

- Speed Range: 3,000 rpm.

- 1” Dual Cross Over Relief Valve (Hydraulic Motor Safety)

- Power Output and Speed at 1800 RPM of Engine (Powerpack):

- Upper Drum: Power: 4500 to 7800 lbs at 1st gear & Speed: 2200 to 3600 fpm at 4th gear

- Lower Drum: Power: 5000 to 8900 lbs at 1st gear & Speed: 1800 to 3000 fpm at 4th gear

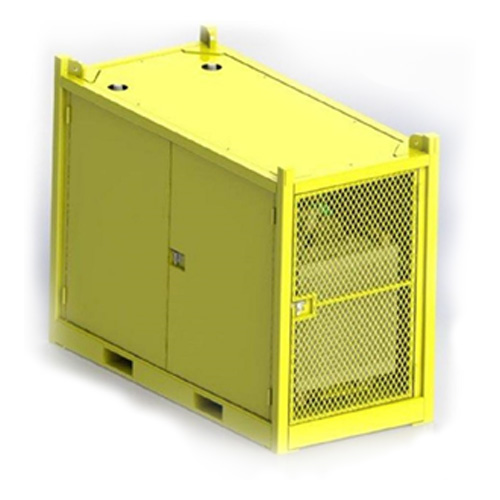

Zone 2 Powerpack Unit

Feature:

- All Steel Welded Crash Frame

- 4 Point Lifting Eyes

- Forklift Pockets

- Protective Moving Parts Guard and Side Frame

Hydraulic System:

- Open Loop System

- Eaton-Vickers Hydraulic Pump Model 35VQ35

- Relief Valve CT 10 F 30

- Hydraulic Oil Cooler

Zone 2 Specification:

- Perkins Engine: 4 Cyl Type 1104A-44T or 6 Cyl

- Variable Speed Engine, IOPU type

- Chalwyn air intake over speed shutdown valve completed with air intake flame trap

- Manual shut-off lever for over speed shutdown valve

- Exhaust gas manicooler, designed to limit temperature of exhaust gas and cooler surface to T3 (200o C).

- Exhaust Flame Trap

- Fuel and Water Coolant to T5 (100oC) Safety Shutdown Valve

- Stainless Steel Spark Arrestor

- Engine Safety shutdown system, designed to give automatic shutdown of both intake air and fuel in the event of:

- Engine over speed

- High Coolant Temperature

- Low Oil Pressure

- Fuel Control Safety Shutdown Valve

- Radiator fan assembly (with non-metallic fan and anti-static fan belt) and radiator

- Secure Screwed Dipstick

Dimensions & Weights

- Transport Dimensions: L 2,300 MM x W 1100 MM x H 1,762 MM (Include lifting pad eyes)

- Weight: 3,000 kgs

Our Suppliers